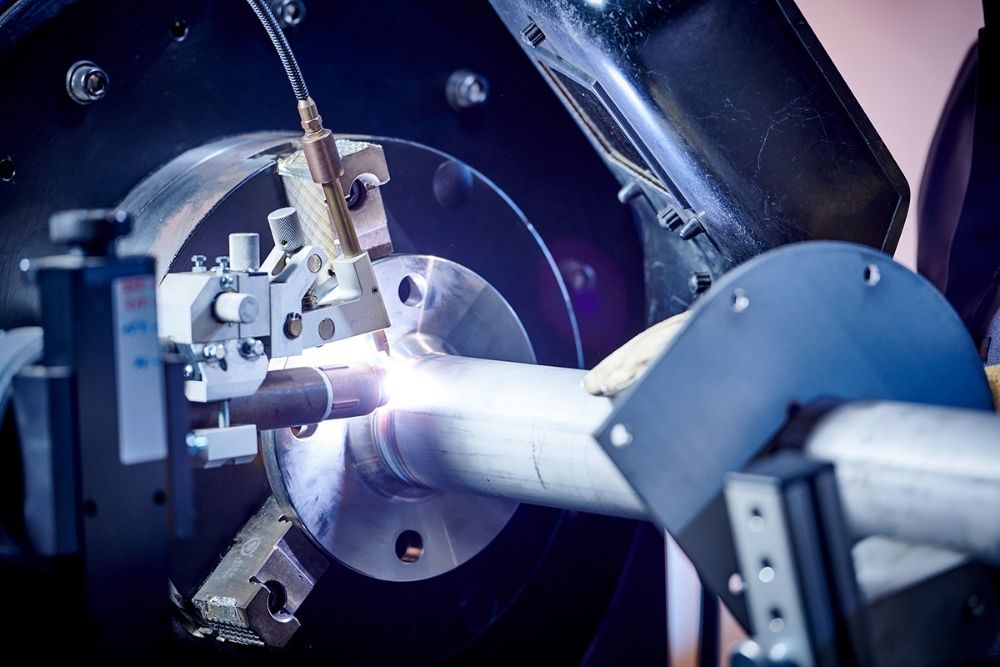

Pipespool production

Flexible and economic piping solutions

As reliable and professional experts, we supply our customers with prefabricated, ready-to-install pipelines. Pipespools are manufactured to customer specifications and to recognised standards in our certified works in Bremen. In close cooperation with our customers and with the involvement of high-performance, well-qualified partners, we resolve all questions of detail and develop an optimised package of services. We stand for quality, commitment, short delivery times and competitive solutions.

In the range of dimensions from DN12 to DN1000, we process all common metals for applications in shipbuilding, various sectors of plant construction and industry in general.

- Processes perfectly attuned to each other ensure quality and delivery dates

- Numerous approvals and appraisals: EN 3834-2, ISO 9001:2015, DNVGL, DIN 2303

- Efficiency at the highest level: 3-D detail design in CADMATIC for basic and detail design

- Capacity planning: detailed production documents and piece lists to control orders

- Great flexibility in cutting, deforming and welding the components due to our extensive stock of machinery

- Reliable material tracing to ensure a smooth manufacturing process

- Certified quality management: documentation and a permanent review of processes

- Servicing and safety: in-house checks, such as pressure, RT, PT, US

- Documentation for reliable production and processing of pipes

You can find information on our raw production products under:

Pipespools according to isometric drawing

Process pipelines

Double-walled-pipelines

Pressure vesseles

CIG – Customized manufactures in batch size 1

CIG Piping Technology GmbH designs and produces tested pressure vessels conform to the individual requirements and specifications of our customers – application-related and product-oriented. The latest production technologies, quality management with the relevant accompanying documents and well-trained staff guarantee quality and a smooth production process.

- Manufacturing range: one-off construction through to small series products with single acceptances

- Production according to PED – AD2000 or DNVGL

- Available up to around 5,000 litres

- Material = C-steel P235, P355 and CrNi-steel 1.4301, 1.4404, 1.4571

- Specification, calculation and detailed design

- Material procurement and production

- Non-destructive testing of welded seams and pressure testing of the finished vessels

- Acceptances in accordance with specifications

- Vessel documentation

You can find information on pressure vessel products under:

Pressure vessels

Serial parts

Piping elements in large numbers

We continuously produce serial parts (such as cooling water pipes and manifolds) in numbers of up to 1,000 pieces p.a., made of metals for various applications on ships and in technical facilities. We can thereby fall back on many years of know-how in pipe processing and use optimised processes for production.

- Automated welding procedure

- Optimised processes

- Own production of construction gauges

- High-performance partners

- All testing performed in-house

- Short delivery times

You can find information on our serial parts products under:

Serial parts